As companies evolve to shift towards automation, demand for revolutionary automated tools has also increased dramatically. In this realm of automation, one of the tools that have been showing promising results is benchtop dispensing robots. At present, these robots are used in a variety of industries. Several new trends and innovations can be seen in these robots, which are helping industries shape their future automation operations and fulfill a broad spectrum of needs.

In this blog, we shall unwind a few of these trends and innovations and understand why benchtop robots are becoming so popular.

Artificial intelligence (AI) and machine learning (ML) are changing the way people used to perceive things. Today, almost every modern tool demands the integration of these evolving technologies, and benchtop robots are no exception.

1. The Rise of Intelligent Dispensing

Working in an industry like that of medicine where accuracy and efficiency are the driving force of their operations, incorporating a highly reliable tool that is fast and adaptable plays a very favorable role. Can you imagine how revolutionary the medical industry can turn into if these tools are fused with technologies like AI or ML? Since these technologies enable the tools to learn from past operations and then adapt to the changing tasks; this helps in optimizing their performance in real-time and ensuring precision. Oftentimes, some batches of chemicals may exhibit changes in their elements. In this case, benchtop dispensing robots powered by AI can use the preset instructions and use them to strategize their dispensing consistency in real-time, ensuring proper chemical quality. This is done without any human intervention, which additionally saves labor costs and omits the probabilities of human-driven errors.

Additionally, these sophisticated technologies are designed to enhance the robot's reliability. The AI or ML can analyze the data of the robot's operations to check for any possible issues or risks with the robot. Such a preventive system can protect the robot from any wear and tear and support its maintenance, leading to the longevity of the robots. Thus, it's also safe to say that automated benchtop robots are a more cost-effective investment.

2. Enhanced Connectivity and Data Integration

Imagine how productive it would be to sit in a space away from the working zone and get the chance to manage other operations while you supervise the working of these automated robots. With the Internet of Things (IoT), automated benchtop robots are being integrated into a network of smart devices, which allows users to track the real-time performance data, material usage, and even anomalies of these robots. This feature builds a seamless connection between the devices and the remote operators who can check for any disintegration in the device or the process and accordingly adjust the parameters of the operation, ensuring high-quality products without compromising on the efficiency level.

Cloud computing is another technology that is changing the paradigm of automated benchtop dispensing robots. With thousands of innovations and discoveries taking place each day, it becomes very important for manufacturers and operators to keep track of the changing trends and optimize their products with updated innovations. Cloud computing will help individuals store data from dispensing operations in the cloud. This data can be accessed in real-time by any remote operator or manufacturer who can use these valuable insights to adjust their dispensing protocols and integrate innovative approaches in their products without needing to be physically present at the location of the operations.

3. Miniaturization and Customization

If you are dealing with industries like electronics and automotive, you'll probably understand the need for automated devices that are designed to carry out precise operations on a higher efficiency level. In these industries, miniaturized benchtop dispensing robots play an indispensable part. Miniaturized robots are usually smaller in size and are more compact than the usual traditional benchtop robots. These dimension features make the robots ideal for scenarios where the dispensing of tiny components is required in tight spaces with precision and efficiency. Especially in the electronic industry, these robots are used to integrate delicate and intricate solder paste on tiny circuit boards without jeopardizing the construction of the overall product. This helps in keeping up with high-volume orders without sacrificing quality and functionality.

These robots can also be tailored to meet customized demands. With the rise in demand for personalization of products, manufacturers often have to struggle to fulfill their client's specific needs. Benchtop robots come with various flexible and versatile adjustments, such as different sizes of dispensing heads, interchangeable nozzles, easily manageable integrated software, and other features that allow these robots to customize products of a wide variety and therefore make them a valuable tool for several industries.

4. Sustainability and Eco-Friendly Practices

There are already enough talks about sustainability and eco-friendly practices that people are unaware of. What's astonishing is that these practices are also becoming a core value for the existing and upcoming businesses that strive to contribute to environmental safety through their eco-conscious product building. Among many tools that are helping such individuals achieve their sustainability goal, the benchtop dispensing robot is one. The automation-driven operations of these robots ensure precision, which minimizes the waste of products or the usage of extra materials than required, contributing to sustainable practices.

Besides, the automation system of benchtop dispensing robots also enhances their performance efficiency, which increases mindful usage of energy and reduces the environmental footprint, which is another crucial factor in achieving eco-friendly goals. Furthermore, modern innovations in benchtop robots, such as low-power components, energy-efficient motors, and optimized control systems, contribute more to this noble cause.

Future Prospects

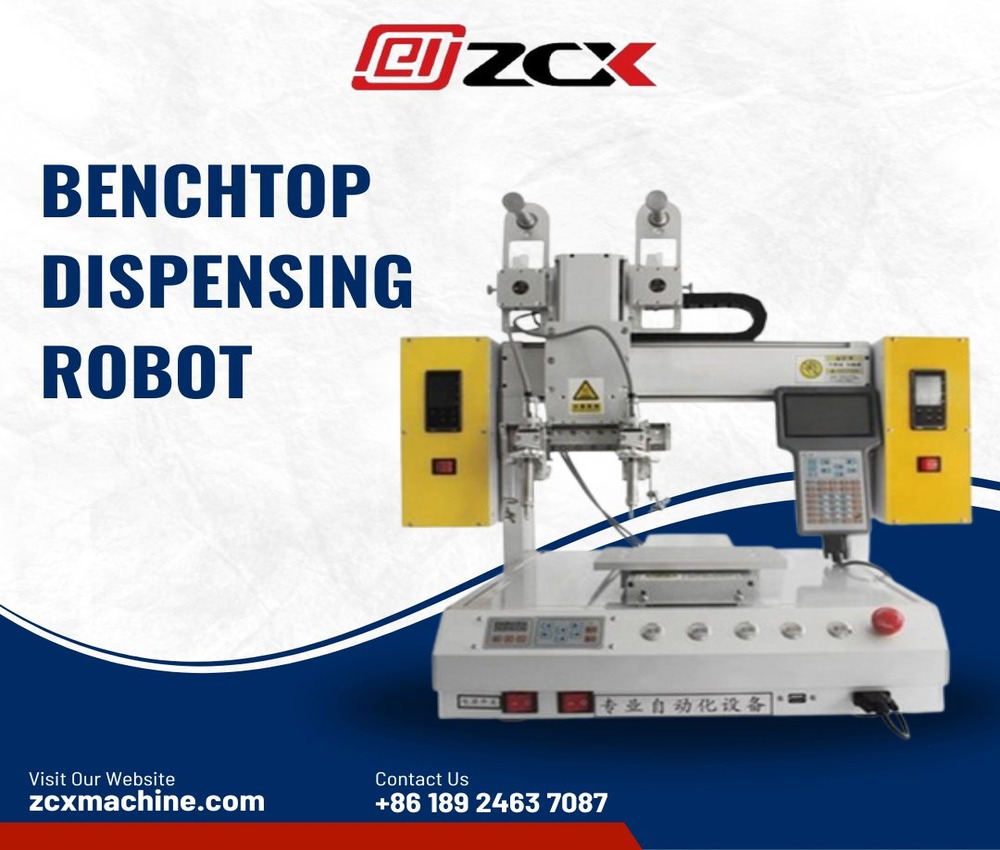

The future of benchtop dispensing robots is therefore brimming with endless possibilities as technology continues to evolve, allowing businesses to unlock new levels of productivity and quality by expertizing on these changing trends and innovations. With ZCX, you can get ahead in this innovation race by using our high-quality benchtop dispensing robots. Our robust robots are designed for a versatile range of benchtop dispensing operations across industries like electronics, medicine, automotive, battery, decoration, LED lighting, and other specific industries. Our benchtop robots are meticulously engineered to surpass your expectations and keep your manufacturing processes smooth, efficient, and reliable for the long run.