For the first step you need to selecting the Right Potting Compound for Your Application

SUMMARY: Many questions arise when trying to select an appropriate potting compound. Our experienced materials expert can help identify the primary concerns, recommend materials, provide testing of the materials, and offer information on dielectric strength, adhesive characteristics, thermal conductivity, and more, through the testing process.

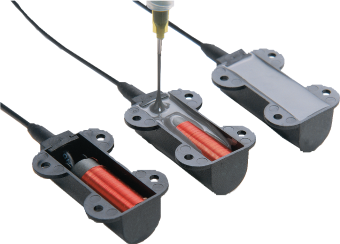

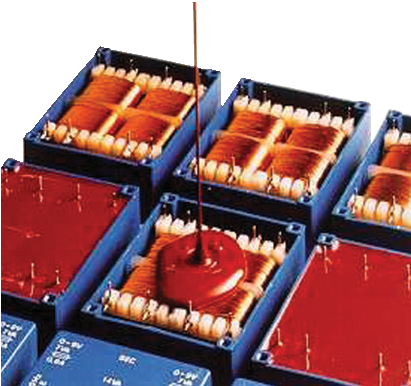

Potting materials for electronics and electrical equipment industries cover a device or component to protect it from the surrounding environment. Embedding a device or component in a resin compound can secure it in the assembly, as well as protect it from moisture, and electrically insulate it so that it will perform as designed.

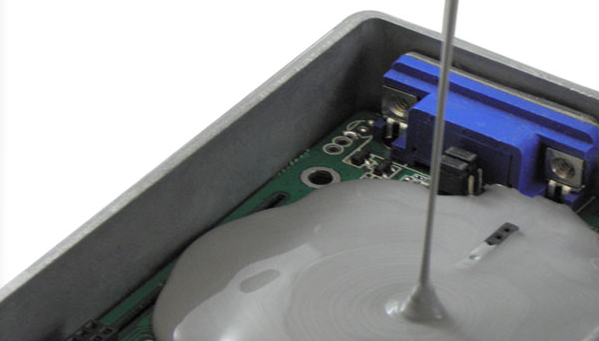

Potting gets its name from the use of a “pot,” case, or shell that surrounds the device, into which the liquid potting material/compound is introduced. Potting can be performed manually or using automated meter-mix-dispense (MMD) equipment.

What is the acceptable curing time or gel time? What is the curing mechanism? UV? Room temperature? Oven? What are the adhesive characteristics required by the application? Durable hard bonding? Flexible bonding? What is the coefficient of thermal expansion (CTE) of the potting compound? CTE of differences between potting compounds and components may cause stress or even fracturing of fragile component parts.

Will the potting compound be applied manually or as part of an automated process? How many parts will be made per hour? What is the shot size?Will the material need to be flame-retardant?What is the desired hardness of the cured compound? What is the overall cost? Component parts?Compound? Final product?What is your requirement of production capacity?Want it be in automatic production line?

These are just a few examples of the considerations to be examined during the potting compound selection process. Our experienced materials expert can help to identify the primary concerns, recommend materials, provide testing of the materials, and offer information on dielectric strength, adhesive characteristics, thermal conductivity, and more, through the testing process.

Types of Potting Compounds

There are a variety of potting and encapsulating compounds to consider. The most popular are: epoxy, hot melt, unsaturated polyesters, urethanes and silicones.

The thermal properties of epoxy allow it to work well in applications where it may be exposed to temperatures from 125°C to 155°C. In some cases, there are specially formulated epoxy systems that can be exposed to higher temperatures up to 220°C. Epoxies are very predictable and stable before, during, and after processing. In addition, they offer good chemical resistance with the exception of acids. They provide excellent strength and adhesion, especially to metals and porous surfaces.

Moreover, they have a full range of hardened properties depending on the formulation. UV cure versions are available.

Standard rigid epoxies are not well- suited for high-impact applications, unless flexibilizers are added to their formulations. Small cracks in a hard- ened epoxy can become large and easily spread. They are not well suited for PCBs with surface mount technology (SMT) components because they can be too rigid once cured. They do not bond well to flexible plastics and, when bent, the bond can be easily broken. They do not work well with low surface energy (LSE) plastics, as they do not adequately wet the plastic.

Hot melts are easy to use, fast to set, and provide great gap filling. They can be easily removed for repair and rework. They have low heat resistance but good solvent resistance. Hot melts can be polyamide, polyurethane, and polyolefin based. They have a low viscosity when applied at an elevated temperature and they set at room temperature. The polyolefin-based hot melts can be used with LSE plastics that are hard to bond.

Hot melts have a fast average set time of 60 seconds and an unlimited depth of application. They are a cost-effective material.

Unsaturated polyester resins are commonly used in electrical potting applications. The formulas’ mechanical characteristics range from flexible to rigid and can be used in at temperatures up to 180°C. Chemical resistance of these materials is fair. Their adhesion to metals is good. Their applied cost is made more economical with the addition of inorganic fillers. The addition of fillers reduces shrinkage during cure.

Urethanes have a broad range of hardness characteristics. With a glass transition temperature (Tg) below -40°C, urethanes are a good choice for PCBs with SMT. Gel times can be easily changed with different formulations to speed up the process. They are suitable for use in applications with operating temperatures up to 130°C. Some specially formulated urethanes can withstand operating tempera- tures up to 150°C. Chemical resistance is good; however, they cannot be totally immersed in chemicals without failure. They do not work well with LSE plastics, as they do not adequately wet the plastic.

Urethanes can be rigid to flexible and cure at room temperature. They are ideal for potting applications that require flexible bonds.

Silicone is adaptable to temperatures ranging from -65°C to 200°C. It has a Tg of -40°C, making it a good match for SMT applications. They provide a soft, flexible bond that can be UV cured. Solvent resistance is good, and silicone has a shallow depth of cure and low strength. Adhesion without a primer can sometimes be a problem. High cost is the biggest issue with silicone. It does not work well with LSE plastics, as they do not adequately wet the plastic.

Advances in UV curing are allowing design engineers to use different materials for given applications. UV curing materials cure, or harden, when exposed to UV light. The benefits of UV curing include:

UV light sources should be selected for power, spectral output, distance to the substrate, and age of the lamp. High-intensity lamps produce more UV for faster cures, but they also increase heat and are not recommended for heat-sensitive applications.

Numerous potting applications exist, including:

As design engineers in all of these industries continue to make electronics assemblies that are denser and more powerful, the right selection of potting compounds for the application is more important than ever.

Our experienced materials specialist can help design engineers test the materials for a specific application. This expert can investigate the appropriate potting formulations that will work with the substrate, end-use, and manufacturing process. With an in-house test laboratory, an experienced materials specialist and flexible materials converter, like Fabrico, can look at alternative compounds based on the customer’s specifications.

Our materials specialist will offer full integration with the your engineering staff, including 2D and 3D CAD design capabilities, integration of the your electronic drawings, and rapid prototyping capabilities for thorough design vetting before manufacturing.

For potting compounds, our materials specialist are able to provide packaging/repackaging to fit the your manufacturing process, including:

In addition, ongoing materials and compounds research will discover new solutions for customer applications in potting and encapsulating.

As Published in SMT Magazine (September 2012)

by Craig McClenachan, Fabrico and Jim Stockhausen ELANTAS PDG, Inc.